- News

As industries increasingly turn to gasification as a key technology in the transition to low-carbon operations , the need for robust and efficient system components becomes more critical. Sumitomo SHI FW (SFW) continues to lead in this space with innovations that improve the reliability and performance of gasification systems. One such advancement is our invention to improve and develop a gas cooler design tailored for pressurized gasification applications.

Improvements to gas cooler for pressurized gasification

Cooling product gas is a recurring challenge in gasifier applications. This is typically achieved using coil heat exchangers. However, when fouling, corrosion or erosion are potential concerns, an empty pass can be used either as an alternative or an addition to coil heat exchangers. The empty pass is a membrane wall construction with water cooled walls, which lowers the gas temperature as it travels through the pass. This solution is commonly used, for example, in waste-to-energy boilers. Moreover, Japanese patent application Tokkai 2001-324129 describes a gas cooling apparatus for gasification, where the flue is formed by membrane parts that pass and cool the flue gas.

Challenges posed by pressurized gasification

In gasifiers operating at atmospheric or moderate pressure, the empty pass is typically constructed with a rectangular cross-section for ease of manufacturing. Walls are supported with beams, also known as buckstays, to prevent damage and excessive deflection of walls caused by high gas pressures from inside the empty pass. However, in some applications, it is beneficial to operate gasifiers at higher pressures, ranging from a few bars up to several tens of bars. With high gas pressures, rectangular passes are problematic as gas pressure induces high bending loads on the walls. Practically, this would require denser buckstay spacing and larger buckstays, making the rectangular cross section potentially unfeasible. Structurally, a circular cross-section would be preferable for holding the internal gas pressure, but it is more complex and costly to construct.

Gas cooler with polygonal cross-section

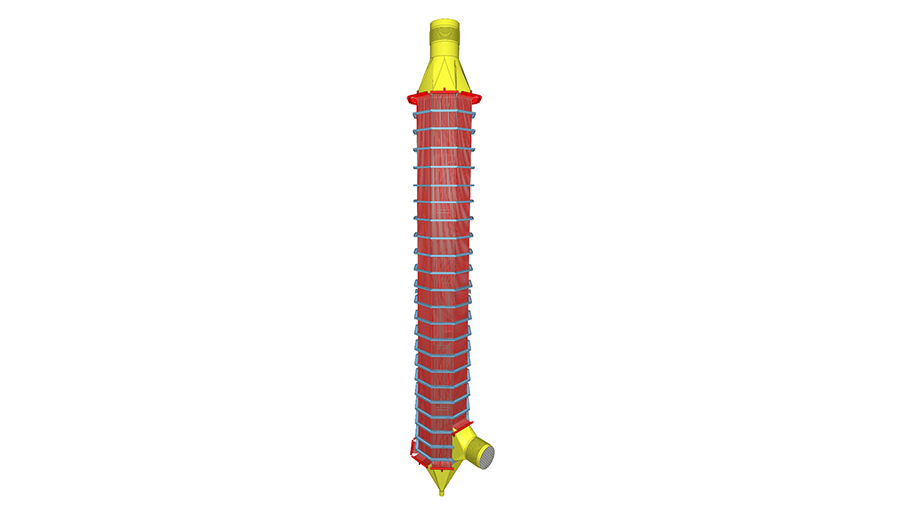

To combine the manufacturing simplicity of a rectangular cross-section with better pressure bearing advantages of a rounded design, the gas cooler can be constructed in a polygonal shape with five or more corners. This solution is inspired by one of SFW’s time-tested cyclone separators, as disclosed in international patent application WO0176722A1. More specifically, the gas cooler main body consists essentially of vertically extending membrane walls that form an approximately regular polygon.

The polygonal gas cooler concept offers a practical solution for pressurized gasification systems, balancing structural integrity with manufacturability. It reflects SFW’s commitment to advancing reliable, cost-effective technologies that support the global shift toward cleaner energy.

Image